Reliable Wall And Ceiling Framing Systems Manufacturing Solution

- The raw material is galvanized steel.

- Thickness ranges from 0.4 to 1.15mm.

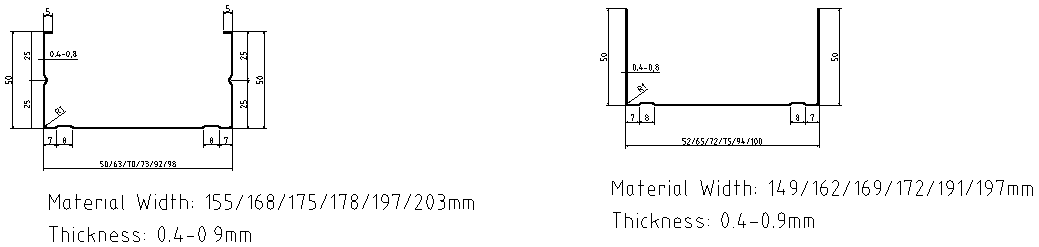

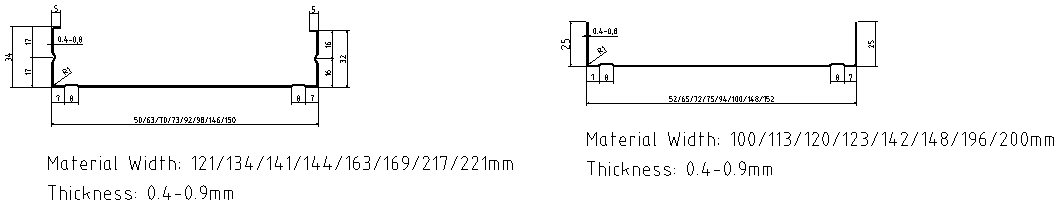

- C stud is between 50-150mm width and 32-50mm height.

- U track is between 52-152mm width and 25-50mm height.

- Rollformer software achieves web and flange interchangeable system.

- 30m/min, 50m/min, 70m/min line speed available.

- Integrateknurling, embossing, punching, roll forming, printing, and cutting solutions.

Reliance Stud And Track Roll Forming Machine Assure Your Wall And Ceiling Framing Systems Quality Perfect

Custom Your Own Stud And Track Roll Forming Machines

Metal C stud and U track is the lightweight steel framing system and cost-effective solution for building non-load bearing drywall partitions quickly and efficiently. Because of the type and size of stud and track, it’s suitable for most domestic, commercial, and industrial buildings where a system is required that is both quicker to install and lighter than both timber and block partitions.

Reliance stud and track roll forming machine is an automatically adjustable roll forming system that can produce the most commonly used stud and track sizes in one machine. It’s high volume and quality solutions for stud and track production. It’s also named metal stud machine, metal stud forming machine, stud roll forming machine, metal stud roll forming machine, steel stud roll forming machine, drywall stud roll forming machine, c stud roll forming machine, metal stud roll former, etc.

Reliance Stud And Track Roll Forming Machines Use the Famous Brand For Critical Parts

Storage & Logistics

Reliance developed the 70m/min line speed with all operations. It much improves efficiency and saves the floor space. Besides, it achieves to automatic change the stud and tracks size without changing rollers. C stud is between 50-150mm width and 32-50mm height. U track is between 52-152mm width and 25-50mm height.

This machine can produce both C stud & U track in one machine. Line speed is 50m/min with all punching and cutting.

Both stud & track can be made in one side-by-side stud roll forming machine. If you only need to provide one kind of stud and track, this design no need to change rollers and shear blade.

It’s our standard line speed with stud roll former. With adjustable roll former, various stud and track sizes can be produced in this machine.

To produce more stud and track sizes in one machine, there are split spacers used for different sizes. Therefore, this metal stud forming machine can produce specific stud and track sizes.

This machine can produce various wall framing studs and tracks without changing rollers. It’s also called drywall profile roll forming machine.

It’s also called metal stud roll forming machine, drywall stud roll forming machine, or c stud roll forming machine. It mainly makes the stud and track used for ceiling framing system.

It mainly makes the stud and track used for the partition framing system.

Why Reliance Stud And Track Roll Forming Machine

Reliance experience, industry knowledge, and designs will assure you to successfully startup your business in the metal lightweight building system.

Our stud and track roll forming machine has the following advantages

- Raw material: this machine normally proceeds galvanized steel of 0.4-1.5mm thickness G550 high strength.

- Web width adjustable from 50 mm to 152 mm, flange height adjustable up to 50mm. It can produce C stud and U track in one machine.

- Line speed is up to 90m/min include roll forming, punching, and cutting operations if the cutoff length is 3000mm. Our developed electrical control system assures stable and precise running.

- Metal stud machine usually consists of manual decoiler, entry guide, hydraulic punching, roll forming, flying shear, inkjet printer, runout table, etc.

- Multi stations punching design in metal stud forming machine, which can punchscrew hole, chamfer notch, web throughout hole, small side shear, pipeline hole, web necking, web foundation hole, etc. The tolerance for punching is ±0.5mm.

- There are dimpled and notched holes so that fasteners install it to a complete frame.

- To the complete system, there are also solutions for the runner, furring channel, angle steel roll forming machines. It’s complete solutions for the steel framing system.

- Knurling can increase the strength of stud and track. The knurling rollers are added before roll forming so that it can use thin material with high-quality products.

- Automatic web and height change system much improve the changeover time and convenience to change size. Besides, it much saves the cost of invest in the machine and less floor space.

- Ink-jet printer. It’s integrated with the operation of roll former and can continuously online print the product information.

- Parameters

- Equipment list

- Layout Drawing

- Profile drawing

| Technical Parameters | ||||

| 1 | Suitable Material | Galvanized Steel Coil | ||

| 2 | Material Width | According to Profile Drawing | ||

| 3 | Material Thickness | 0.5-1.0 mm | ||

| 4 | Roll forming speed | 10-15m/min (Exclude Punching & Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic Decoiler with coil car | 1 set | ||

| 2 | Hydraulic Pre-Punching Device | 1 set | ||

| 3 | Rollformerwith tooling | 1 set | ||

| 4 | Hydraulic cutoff machine (Option: Flying Shear) | 1 set | ||

| 5 | Run out table or automatic stacking device | 1 set | ||

| 6 | Siemens Or MitsubishiPLC and Touchable Screen are used for data processing and setting | 1 set | ||

Reliance Stud And Track Roll Forming Machines

- Wall Framing Stud And Track

- Ceiling Framing Stud And Track

- Partition Framing Stud And Track

Wall Framing Stud And Track

Wall framing stud and track are accurately roll-formed by the stud and track roll forming machine. This system is an ideal durable and lightweight solution for internal and external wall framing system. Through Reliance metal stud and track roll forming machine for sale, you can make various stud and track sizes in one machine without changing tooling. Our standard machine can work from 0.45 to 1.2mm galvanized steel.

Ceiling Framing Stud And Track

Ceiling framing stud and track are accurately roll-formed by the stud and track roll forming machine. It provides customized solutions for ceiling framing systems, including concealed ceiling, suspended ceiling systems, direct fix ceiling, stud ceiling, etc. Through Reliance stud roll forming machine for sale, you can make a variety of ceiling framing stud and track.

Partition Framing Stud And Track

Partition framing stud and track are accurately roll-formed by the drywall stud track roll forming machine. The partitioning framing system is suitable for commercial and domestic buildings non-load-bearing partitions. There is a wide range of stud widths from 50mm to 150mm to meet different projects.

Drywall Stud And Track

Drywall stud and track are accurately roll-formed by the metal stud roll former.