Custom Your Metal Glazed Tile Manufacturing Solution

- The raw material is prepainted steel, galvalume.

- Thickness ranges from 0.3 to 0.8mm.

- Normal material width 914mm, 1000mm, 1200mm, 1219mm, 1250mm.

- 5-6m/min speed available.

- Integrateroll forming, step pressing, 3D cutting solutions.

Reliance Glazed Tile Roll Forming Machine Assure Your Roof Tile System Quality Perfect

Custom Your Own Glazed Tile Roll Forming Machines

Reliance Glazed tile roll forming machine is used to produce metal glazed tile, step tile, roof tile, and corrugated tile, etc. It’s also named tile forming machine, step tile roll forming machine, roof tile roll forming machine, corrugated tile forming machine, etc. The glazed tile is much different from traditional ceramic roof tile, with lightweight, energy-efficient features.

Reliance tile forming machine can proceed prepainted steel coil, galvalume, etc. The typical material thickness is from 0.3 to 0.8mm. In some particular cases, Reliance machinery also can proceed with 0.25mm thickness material. The material width will be between 914mm and 1250mm.

Reliance Glazed Tile Roll Forming Machines Use the Famous Brand For Critical Parts

Storage & Logistics

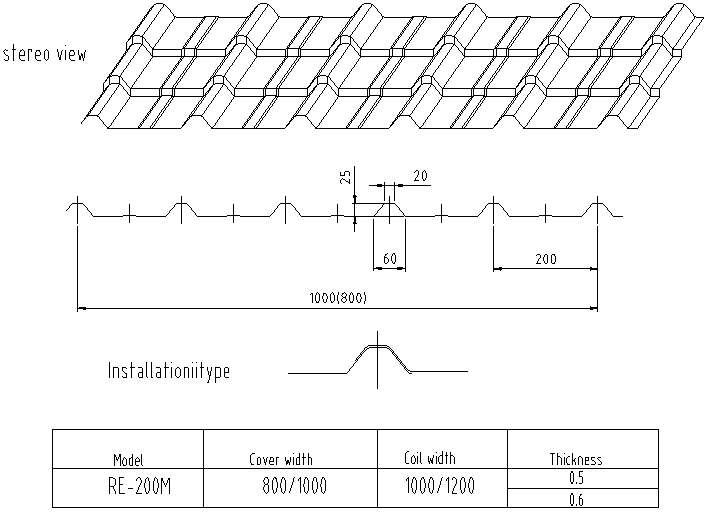

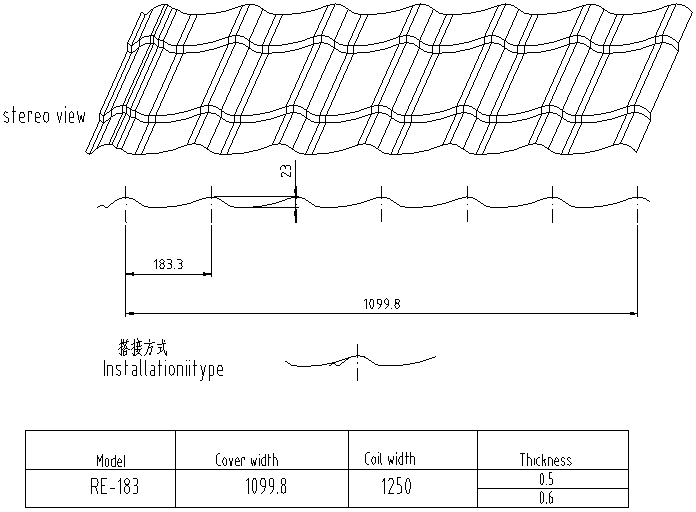

RE25-183.3-1100 glazed tile roll forming machine is a classic model in the European market. This glazed tile forming machine can reach 5-6m/min line speed includes the step pressing and cutting time. The operator can set the step length and tile length in the HMI.

RE27-190-950 step tile roll forming machine is a classic model in the India and Africa market. The main motor of tile forming machine is servo motor so that it can assure the tile step accuracy and faster speed. The line speed is about 5-6m/min line speed includes the step pressing and cutting time. The operator can set the step length and tile length in the HMI. It’s flexible to set the tile step length and tile length in the touch screen.

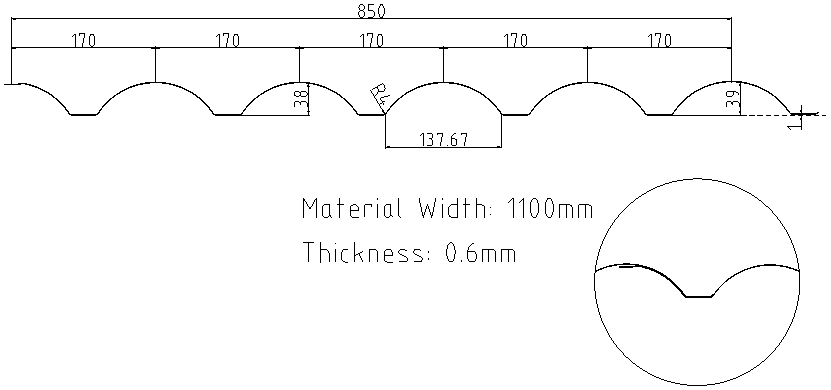

RE38-170-850 roof tile roll forming machine is a new roof tile model making bamboo shape roof tile. Our roof tile forming machine can achieve automatic uncoiling and auto stacking. Line speed is about 6m/min includes the step pressing and cutting time.

RE28-207-1035 high-speed glazed tile roll forming machine is a high-speed type tile forming machine. It intergrades full automatic types of equipment, includes hydraulic uncoiler and coil car, automatic stacker, etc.

RE25-183.3-1100 tile roll forming machine is with 3D cutting in tile ends. The normal glazed tile roll forming machine is with straight cutting. If use 3D cutting, the roof tile end looks closely with clay tile.

Why Reliance Glazed Tile Roll Forming Machine

Tile roll forming machine is different workflows compare to the roof roll forming machine. The difference is pressing the steps every 300mm length. This step takes much time in the process. Therefore, Reliance developed a high speed glazed tile roll forming machine with 5-6m/min line speed. The normal line speed is 2-3m/min for step tile roll forming machine.

You can set the step distance according to the customer’s order.

About the step depth, it’s basically designed by pressing mold. The most step depth is between 15 to 20mm. Reliance also has experienced up to 25mm step depth. After pressing, there is no scratch on the surface of the roof tile.

There are several cutting shapes of the glazed tile forming machine. The most used cutting shape is straight cutting so that the end of the roof tile is a straight line. There is also corrugated shape cutting or 3D cutting, in which the end shape is similar to the tile step shape. There is only 15mm to 20mm distance to the roof tile step.

In the past years, Reliance developed more than 20 kinds of glazed tile for different countries. You can provide your design or we can suggest some popular models, roof tile forming machinewill be customized designed and meet your market.

Reliance roof tile roll forming machine will help you to catch the market need and grow your business together. If you need, the Reliance technician is available for coming to install machines for you.

Please don’t hesitate to contact us to startup this business.

- Parameters

- Equipment list

- Layout Drawing

- Profile drawing

| Technical Parameters | ||||

| 1 | Suitable Material | PPGI Steel Coil | ||

| 2 | Material Width | 914 / 1000 / 1220 / 1250 mm | ||

| 3 | Material Thickness | 0.3-0.8 mm | ||

| 4 | Roll forming speed | 10-15 m/min (Exclude Pressing & Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic Decoiler with Loading Coil Car | 1 set | ||

| 2 | Rollformer with tooling | 1 set | ||

| 3 | Hydraulic step pressing device | 1 set | ||

| 4 | Hydraulic cut-off machine | 1 set | ||

| 5 | Run out table or automatic stacking device | 1 set | ||

| 6 | Siemens Or Mitsubishi PLC and Touchable Screen are used for data processing and setting | 1 set | ||

Reliance Glazed Tile Roll Forming Machines

- Metal Glazed Tile

- Metal Step Tile

- Metal Roof Tile

Metal Glazed Tile

Metal glazed tile is accurately roll-formed by the glazed tile roll forming machine. Metal glazed tile is with a similar appearance of ceramic tile. The advantages and performance of metal are lightweight, energy-efficient, and outlook attractive. The Reliance team can achieve various glazed tile designs by our glazed tile forming machine. Our standard tile roll forming machine for sale proceeds with 0.3 to 0.8mm thickness and color steel.

Metal Step Tile

Metal step tile is accurately roll-formed by the step tile roll forming machine. The traditional ceramic tile is with small size and overlap together. The metal step tile is made by steel coil with and pressed steps. It looks like to overlap together. Through the Reliance step tile roll forming machine, you can make various step tiles in high efficiency.

Metal Roof Tile

Metal roof tile is accurately roll-formed by the roof tile roll forming machine. It looks like the natural beauty of clay tile roofing in lightweight steel material. The advantages are lightweight, walkable, wind-resistant, strength, and longevity. Reliance roof tile forming machine achieves various roof tile design for your options.