Complete Guardrail Systems Manufacturing Solution

- The raw material is hot rolled steel, galvanized steel.

- AASHTO M180 standard guardrail.

- Thickness ranges from 2.7 to 4.0mm.

- Material yield strength: 345Mpa

- Line speed 4pcs/min if guardrail length is 4320mm.

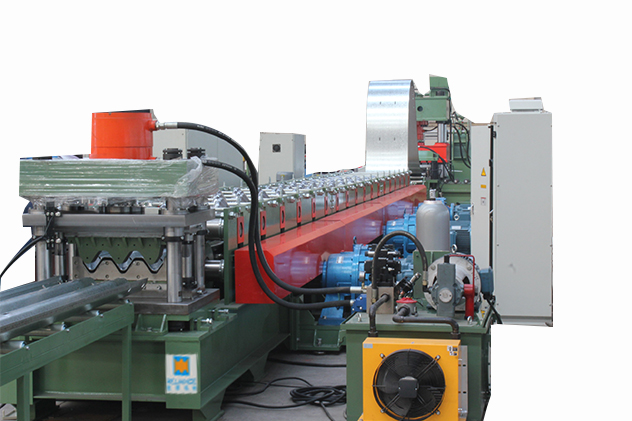

- Integrateleveling, punching, roll forming, flying cutting, auto stacking.

Reliance Guardrail Roll Forming Machine Assure Your Guardrail Systems Quality Perfect

Custom Your Own Guardrail Roll Forming Machines

Highway guardrail systems keep people or vehicles away from dangerous areas and are commonly used as road and highway guardrail barriers. It’s been fixed on the side of the roads, especially on curves and slopes for preventing vehicles drifted off the road. For a highway contractor, a full automatic guardrail roll forming machine is the top choice for high volume and quality guardrails production. It’s also named highway guardrail roll forming machine.

Which types of highway guardrails are produced by highway guardrail roll forming machine?

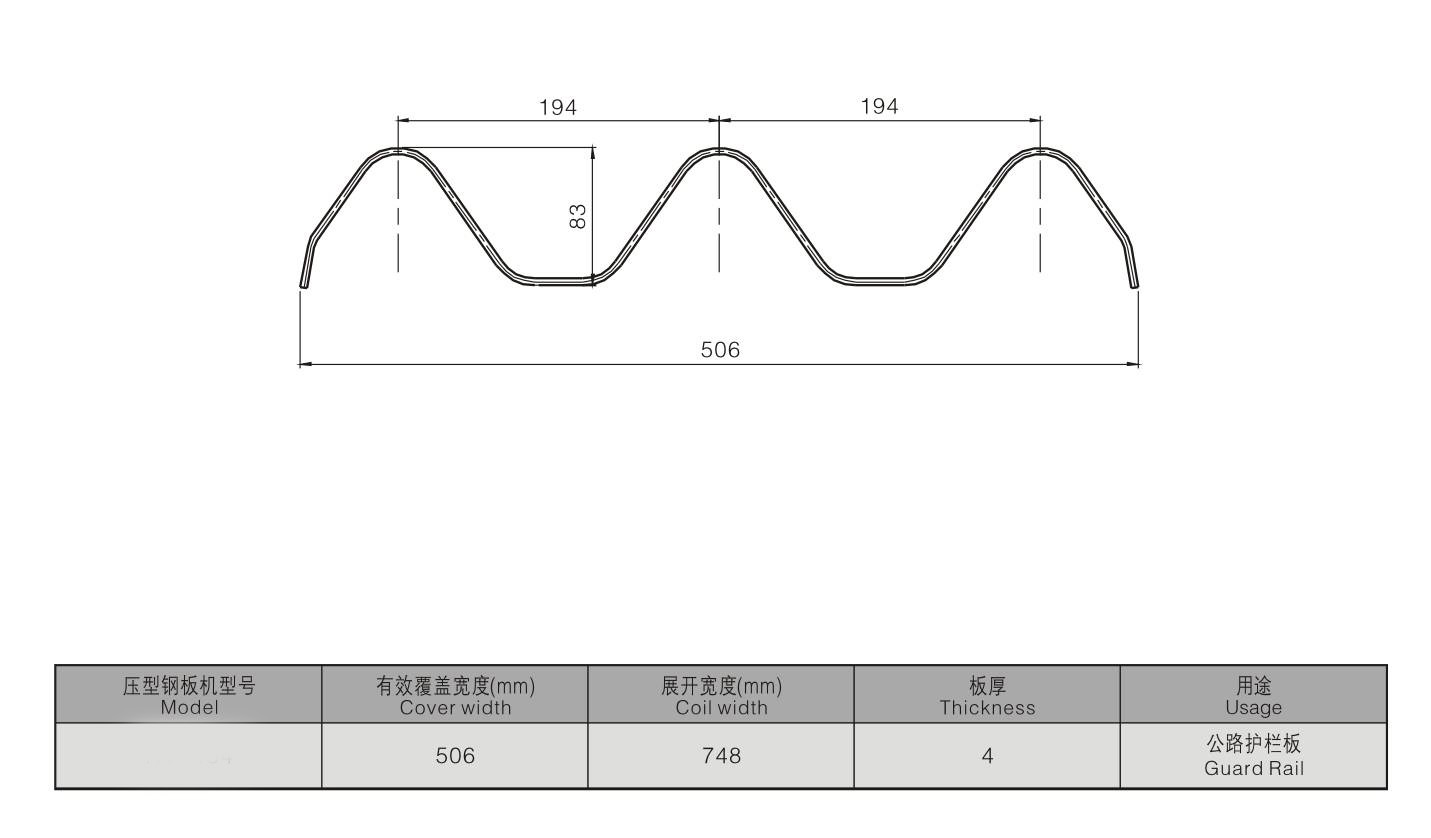

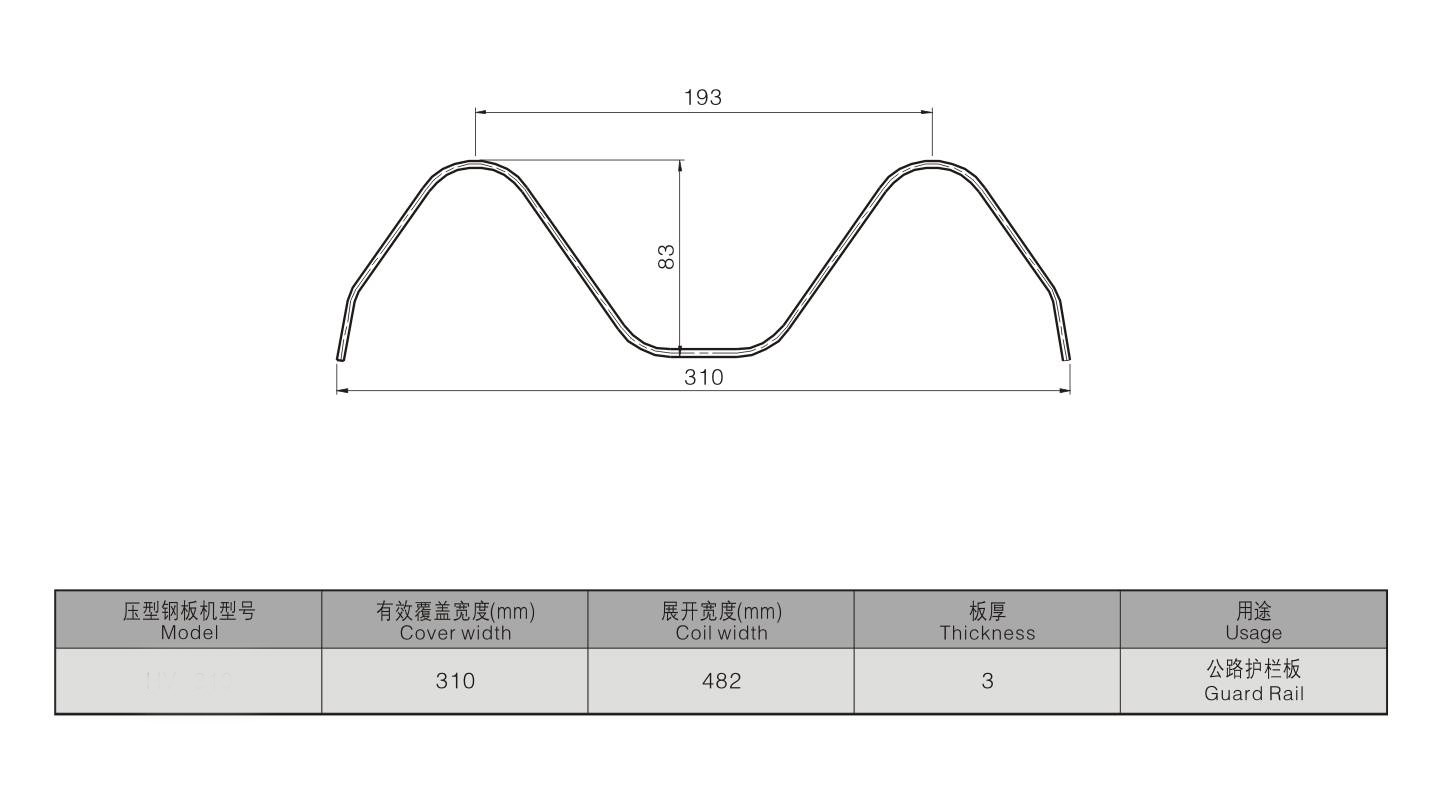

The typical guardrails are W-beam with two waves and thrie beam with three waves. Thrie beam guardrail is with extra corrugation on the basics of traditional W-beam. Compared to W-beam, thrie beam has a stronger construction and higher impact endurance.

There are three types of guardrail forming machines for your options.

- W beam guardrail roll forming machine.

- Thrie beam guardrail roll forming machine.

- Cassette type roll forming machine which can make both W beam and thrie beam in one machine.

Full automatic guardrail roll forming machine includes double-head uncoiler, coil opener, flattener, servo feeder, multi-station hydraulic punching, roll forming,flying shear, and automatic stacker. The final guardrail is used max.3.5mm or 5mm thickness with 4320mm length. It will require robust design and high automation for opening steel coils and stacking finished guardrails.

Reliance Guardrail Roll Forming Machines Use the Famous Brand For Critical Parts

Storage & Logistics

RE85-311 is the most used W beam model in the market. The line speed can reach 16m/min includes punching, roll forming, and cutting. Reliance guardrail forming machine is capable of making up to 4mm thickness and 345Mpa.

RE80-306 is the most used W beam model in the European market. It integrates the uncoiling, leveling, inline punching, roll forming, flying cutting, and auto stacking.

For some startup business, Reliance can provide economic type solution. It’s stop-punching and stop-cutting type. The line speed can reach 8m/min with punching, roll forming, and cutting.

Due to the length and weight of guardrail, the full automatic guardrail roll forming machine is required in the market. Reliance provides the double head uncoiler, coil opener, end shear and welder, leveling, inline multi-station punching, roll forming, flying punching, and automatic stacker. It will only require 2 or 3 workers for one line.

RE83-507 is an upgraded model compare to the W beam guardrail. Reliance provides the thrie beam guardrail roll forming machine with 16m/min line speed.

To save the floor space and machine cost, Reliance developed the cassette type roll forming machine. It can make both W beam & thrie beam guardrail in one machine.

Reliance can provide the separate C, U, Sigma section guardrail post roll forming machine. The cassette type design can make C, U, Sigma section in one guardrail post roll forming machine.

There are different types of terminal sections in the guardrail system. Reliance has solutions to use hydraulic press and punch mold to make various terminal sections.

Why Reliance Guardrail Roll Forming Machine

To combine the multi-station hydraulic punching, flying shear, and auto stacker, Reliance guardrail machine can reach 4pcs/ min ( if each guardrail is 4320mm length). It’s much faster than the common line with 1 or 1.5pcs/min line speed.

- It’s with coil peeler and pressure pad which assistant to open steel coils. It can help to open the steel coil fast and much safety for operation.

- It’s with a much reliable punch tool and high tolerance of hole locations. The efficient hydraulic punching system can complete the AASHTO standard approved punch patterns.

- Robust design of roll forming section, which assures the quality of guardrail dimension.

- Auto stacker is helpful to stack the guardrails and high efficient to stack the finished products.

Please don’t hesitate to ask for a quote.

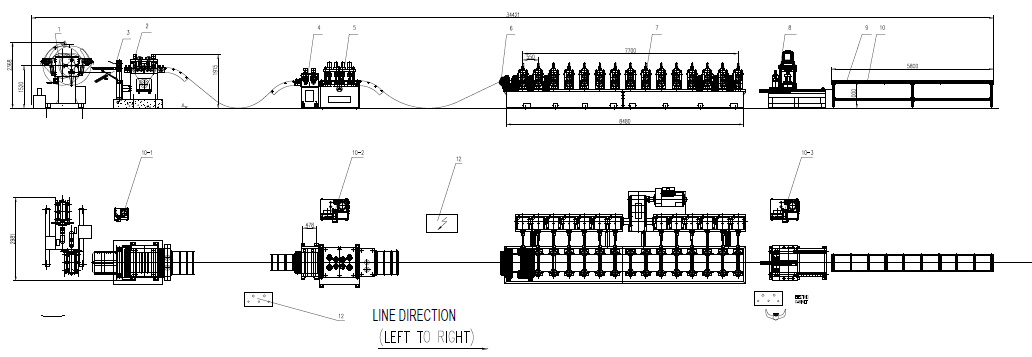

- Parameters

- Equipment list

- Layout Drawing

- Profile Drawing

| Technical Parameters | ||||

| 1 | Suitable Material | Hot Rolled Steel | ||

| 2 | Material Width | According to Profile Drawing | ||

| 3 | Material Thickness | 2.7-3.5 mm | ||

| 4 | Roll forming speed | 10-15 m/min (Exclude Punching & Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic Decoiler with uncoiler | 1 set | ||

| 2 | Loading Coil Car (Option) | 1 set | ||

| 3 | Peeler Table And Pressure Pad | 1 set | ||

| 4 | Leveler | 1 set | ||

| 5 | Hydraulic Crop Shearing And Butt-Welding Equipment(Option) | 1 set | ||

| 6 | Entry Looping Pit | 1 set | ||

| 7 | Servo Roll Feeder | 1 set | ||

| 8 | Online Hydraulic Punching Equipment Or Mechanical Punching Press | 1 set | ||

| 9 | Exit Looping pit | 1 set | ||

| 10 | Rollformer with tooling | 1 set | ||

| 11 | Straightening Device | 1 set | ||

| 12 | Flying cut-off machine | 1 set | ||

| 13 | Run Out Table or automatic stacking device | 1 set | ||

| 14 | Siemens Or Mitsubishi PLC and Touchable Screen are used for data processing and setting. | 1 set | ||

Reliance Guardrail Roll Forming Machines

- W Beam Guardrail

- Thrie Beam Guardrail

- W Beam Or Thrie Beam Crash Barrier

- U/C/Sigma Guardrail Post Or Spacer

- Terminal Section

W Beam Guardrail

W beam guardrails are accurately roll-formed W shapee section bythe guardrail roll forming machine from steel coils. W beam guardrail is the most frequently used type of guardrail on the highway guardrail system. The common use of material thickness is 2.7 to 3.5mm. In some cases, it will be up to 4mm thickness. Through the Reliance highway guardrail roll forming machine, you can achieve full automatic guardrail productions.

Thrie Beam Guardrail

Thrie beam guardrails arecontinuous roll-formed from steel coil by guardrail roll forming machine. Thrie beam guardrail is with extra corrugation based on W beam. The material thickness is up to 5.0mm and stronger than the W beam guardrail. Reliance provides thrie beam guardrail roll forming machine for automatic production.

W Beam Or Thrie Beam Crash Barrier

W beam or thrie beam crash barriers are accurately roll-formed by the crash barrier roll forming machine. The metal beam crash barriers are mostly used in the highway guardrail system. Reliance can provide the best solution for both w beam and thrie beam crash barrier roll forming machine.

U/C/Sigma Guardrail Post Or Spacer

The guardrail posts arecontinuous roll-formed from steel coil by guardrail post roll forming machine. In the guardrail system, it includes the post & spacers. The most used section is U, C or sigma section. The thickness is from 4.5 to 6.0mm. Reliance can provide separate or cassette type guardrail post roll forming machine according to our requirements.

Terminal Section

In the guardrail system, there are some terminal sections. Reliance can provide complete solutions to use a hydraulic press with moulds to make various kinds of end sections.