Reliable Light Gauge Steel Framing Technology

- The raw material is galvanized steel, aluminum alloy, etc.

- Thickness ranges from 0.75 to 1.2mm.

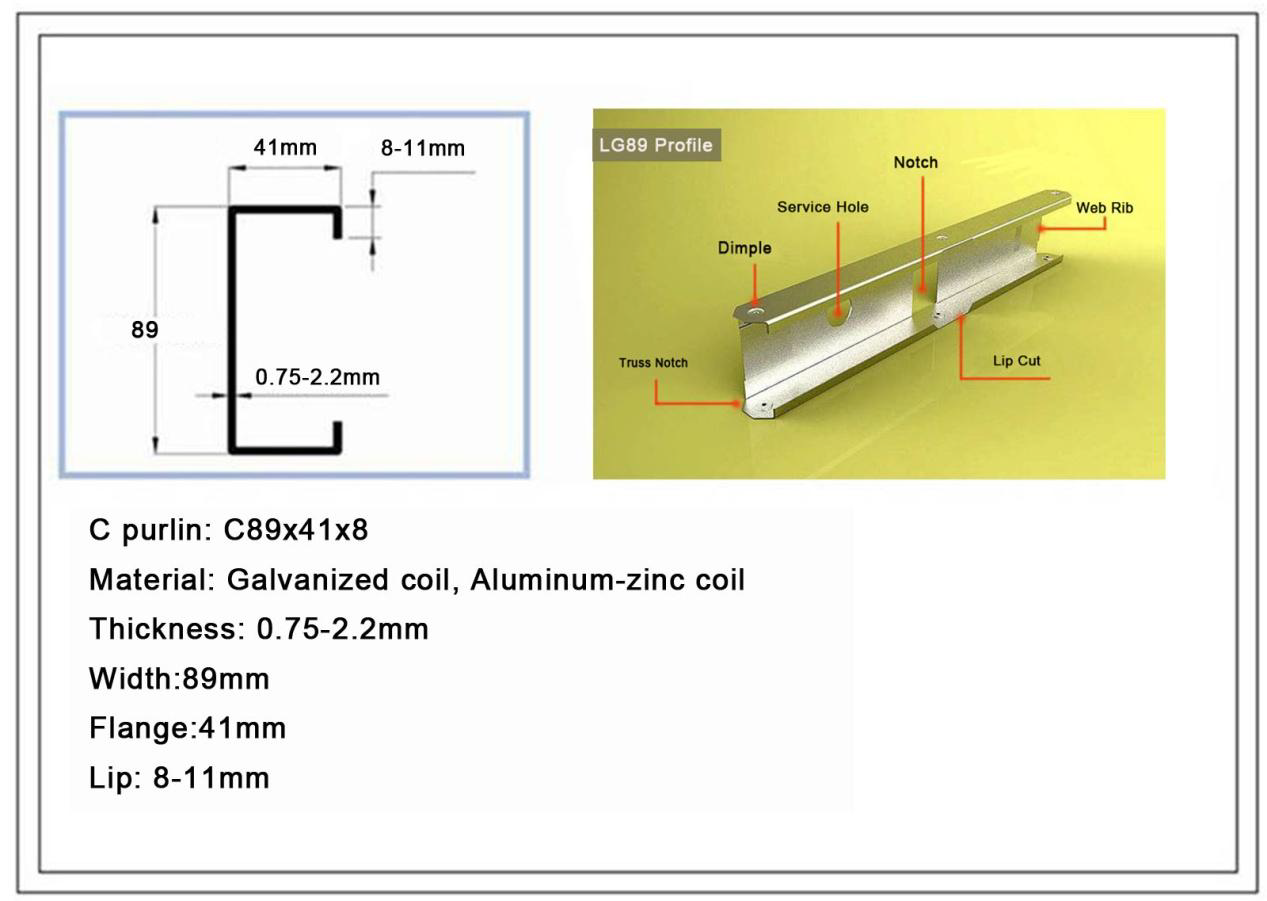

- C stud is 89mm width and 41mm height.

- Complete punching solution to finish truss notch, dimple, service hole, notch, lip cut, and web rib.

- Integrate punching, roll forming, printing, and cutting solutions.

- Vertex BD design software.

Reliance Steel Framing Machine Assure Your Light Gauge Steel Framing Quality Perfect

Custom Your Own Steel Framing Machines

The light gauge steel framing system includes structural frames made by cold roll-formed steel sections. They are used throughout a structure, including load-bearing exterior walls, non-load bearing interior walls, floor joists, curtain walls, and roof trusses. Cold-formed steel sections are lightweight but high tensile and galvanized steel (Z-275gsm / 550Mpa).

Reliance light gauge steel framing machines are designed and manufactured in one high automation, complete, and integrated package. It’s also named steel frame roll forming machine. The function is similar to Howick framing machine for sale.

Reliance Steel Framing Machines Use the Famous Brand For Critical Parts

Storage & Logistics

This machine can produce C stud in 89mm depth and 41mm height, thickness 0.75-1.2mm by galvanized steel, aluminum alloy, etc.

This machine can produce both stud & track in one machine. The roll former is a rapid quick-change design so the operator can set sizes in the touch screen. The line speed can reach 50m/min.

This machine can produce both stud & track by side-by-side roller sets. It will not require to change rollers or shear blade and save floor space.

This machine can produce CU floor joists with adjustable roll former.

This machine can produce the furring channel in 50m/min line speed.

Why Reliance Steel Framing Machine

- Vertex BD Design Software: Use Vertex house design software to design the building fabricated, and generate the NC code of the design data.

- Gear transmission: Precision hard toothed surface gear transmission is adopted between the forming rollers, and the service life is more than ten years with regular maintenance. Forming roller: The forming roller is optimized by the COPRA software and processed by the CNC machining center. It’s are made of alloy die steel and is hardened at an overall HRC60. The service life under regular use can reach more than ten years.

- Punching mold: The special structure design enables complete the punching with a smaller pressure and minimizes the failure rate of the hydraulic system.

- Hydraulic system: The hydraulic system adopts original German Rexroth components and uses the Siemens brand motor to keep the working stability and service life of the system.

- The ink-jet printer connects with the control system of roll-forming. In addition to printing numbers and English, you can also print Bar codes, QR codes, specific patterns (such as company logos), etc.

- Line speed: the wall framing is more than 900 meters/hour, and the truss beam and roof truss are more than 300 meters/hour. If there is a looping pit between uncoiler and roll former, it is expected to improve efficiency by about 15% when producing wall framing.

- Parameters

- Equipment list

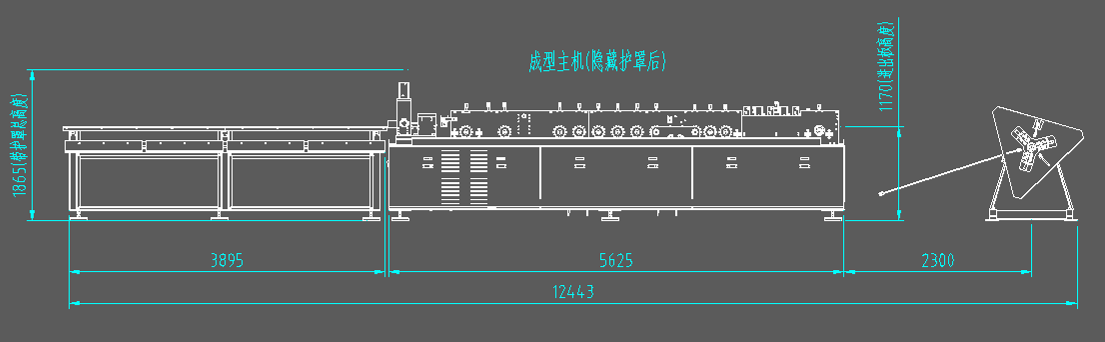

- Layout Drawing

- Profile drawing

- Related products

| Technical Parameters | ||||

| 1 | Suitable Material | Galvanized Steel Coil | ||

| 2 | Material Width | According to Profile Drawing | ||

| 3 | Material Thickness | 0.5-1.0 mm | ||

| 4 | Roll forming speed | 10-15m/min (Exclude Punching & Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic Decoiler with coil car | 1 set | ||

| 2 | Hydraulic Pre-Punching Device | 1 set | ||

| 3 | Rollformerwith tooling | 1 set | ||

| 4 | Hydraulic cut-off machine (Option: Flying Shear) | 1 set | ||

| 5 | Run out table or automatic stacking device | 1 set | ||

| 6 | Siemens Or MitsubishiPLC and Touchable Screen are used for data processing and setting | 1 set | ||

https://continentalsteel.com/carbon-steel/framing-components/

Need to Order Cold-Formed Steel Framing? Start With This Simple Guide

Reliance Steel Framing Machines

- Light Gauge Steel Stud

- Light Gauge Steel Track

- Light Gauge Steel Floor Joists

- Runner Or U Channel

- Furring Channel Or Roof Truss

- Angle Steel Or L Header

- Corner Bead

Light Gauge Steel Stud

Steel stud is accurately roll-formed bythe light gauge steel framing machine. Light gauge C studs are framing members for load-bearing walls, curtain walls, tall interior partitions, floor joists, and roof truss assemblies.The typical thickness range is between 0.4 to 1.5mm. The most use stud sizes are 50mm and 70mm web width.

Light Gauge Steel Track

Light gauge steel tracks are accurately roll-formed by the light gauge steel framing machine. U shape channel is framing members as the top and bottom tracks to protect wall studs or floor joist framing. The typical thickness range is between 0.4 to 1.5mm. The most use stud sizes are 52mm and 72mm web width.

Light Gauge Steel Floor Joists

Light gauge steel floor joists are accurately roll-formed by the light gauge steel framing machine. C shape floor joists provide an excellent flooring system for steel framing.

Runner Or U Channel

U channel runner is accurately roll-formed by the light gauge steel framing machine. U-channel members do not have returns or lips.U Runner is used to protecting H shape hole Stud and gypsum shaft liner panels in area separation wall assemblies. The most common size U 38×12 and 45×15 in 0.4 to 0.8mm thickness.

Furring Channel Or Roof Truss

Furring channel is accurately roll-formed by the light gauge steel framing machine. Furring channels are hat shape steel profiles as framing accessories used to walls and ceilings. The most common size is 68×22 in 0.4 to 0.8mm thickness.

Angle Steel Or L Header

Angle steel is accurately roll-formed by the light gauge steel framing machine. Angle steel used to connect, reinforce, or protect metal stud framing in various drywall applications. The most common thickness is 0.4 to 0.8mm thickness.

Corner Bead

Corner bead is accurately roll-formed by the light gauge steel framing machine. It’s a durable and straight perforated reinforcement for drywall corners.