Reliable CUZM Purlin Manufacturing Solutions

- Raw material: Mild steel, hot rolled steel, cold-rolled steel, galvanized steel, etc.

- Thickness ranges between 1.0 to 4.0mm.

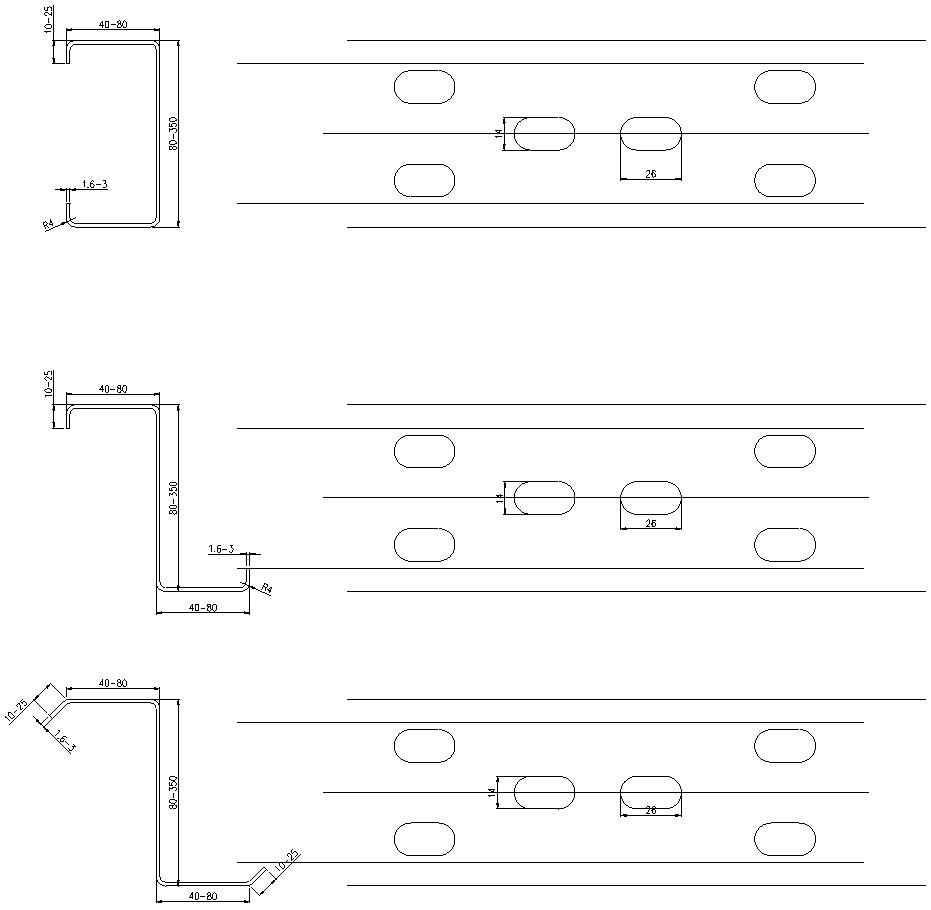

- Automatic web width change C 80-300mm Z 100-300mm Sigma 140-300mm & flange height change 40-80mm without tool change.

- C purlin, Z purlin, Sigma purlin, U steel profile interchangeable in one machine.

- Hole patterns are according to your design.

- Automatic switch C/Z purlin rollformer.

- Universal cutting blade design saves tool changeover time.

- Integrate punching, roll forming, and cutting solutions.

Reliance CZ Purlin Roll Forming Machine Assure Your CUZM Purlin Quality Perfect

Custom Your Own CZ Purlin Roll Forming Machines

CZ Purlins are most commonly used in the steel structure or metal building systems. It’s referred to as roof framing members that span parallel to the building eave and support the roof decking or sheeting.

Reliance CZ purlin roll forming machine achieves interchangeable both web width and flange height change between C, U, Z, and sigma purlin. It’s the best choice for you to develop CZ Purlin production. It’s also named C&Z Purlin forming machine, C Z roll forming machine, automatic c and z purlin roll forming machine, etc.

Reliance CZ Purlin Roll Forming Machines Use the Famous Brand For Critical Parts

Storage & Logistics

This machine can produce C purlin and U purlin 50 to 250mm depth and 25-60mm height, thickness 1.0-2.5mm by hot rolled steel, cold-rolled steel, galvanized steel, etc.

This machine can produce C purlin 80 to 300mm and Z purlin 100 to 300mm depth and 40-80mm height, thickness 1.0-3.0mm by hot rolled steel, cold-rolled steel, galvanized steel, etc. The punching and cutting are placed before roll forming so that it will save cost for the shear blades.

This machine is capable of making C purlin 80 to 300mm depth, and Z purlin 100 to 300mm depth, 40-80mm height, thickness 1.0-3.0mm by hot rolled steel, cold-rolled steel, galvanized steel, etc. The punching and cutting are placed after roll forming. The universal blade design saves the changeover time.

This machine is capable of making C purlin 100 to 400mm depth, and Z purlin 100 to 400mm depth, 40-80mm height, thickness 1.5-4.0mm by hot rolled steel, cold-rolled steel, galvanized steel, etc.

This machine is capable of making C purlin 80 to 300mm depth, U purlin 80 to 300mm depth and Z purlin 100 to 300mm depth, 40-80mm height, thickness 1.0-3.0mm by hot rolled steel, cold-rolled steel, galvanized steel, etc.

This machine is capable of making C purlin 80 to 300mm depth, Z purlin 100 to 300mm depth and sigma purlin 140 to 300mm, 40-80mm height, thickness 1.0-3.0mm by hot rolled steel, cold-rolled steel, galvanized steel, etc.

This machine is capable of the automatic switch make C purlin 80 to 300mm depth and Z purlin 100 to 300mm depth 40-80mm height, thickness 1.0-3.0mm by hot rolled steel, cold rolled steel, galvanized steel, etc.

Why Reliance CZ Purlin Roll Forming Machine

- Reliance CZ purlin roll forming machine can reach the max. 20m/min line speeds

- Automatically adjustable roll former to for web width and flange height change.

- The change process is the only 5min for roll former.

- Besides, there is an option that can automatically switch between C and Z purlin. It much improves efficiency and saves floor space.

- Parameters

- Equipment list

- Layout drawing

- Profile drawing

| Features | |||||

| 1 | Quick C Or Z Change | Infinite varieties of C and Z purline size, without removing tooling or spacers. | |||

| 2 | Quick C to Z Change | Simply rotate the adjustable tooling 180 degrees. | |||

| Work Flow | |||||

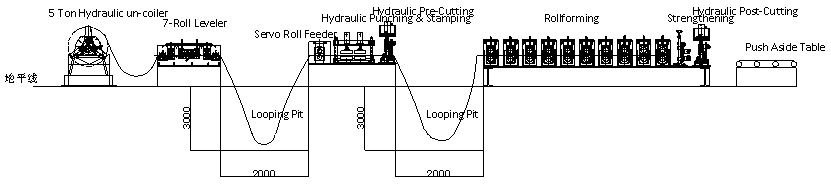

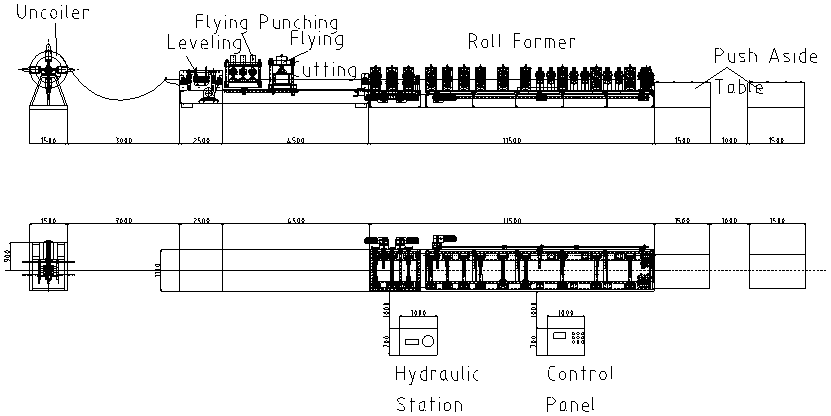

| Option 1: De-coiling→Entry Guide→Leveling→Pre-Punching→Pre-Cutting→Adjustable Rollformer→Straightening→ Run Out Table | |||||

| Option 2: De-coiling→Entry Guide→Leveling→Adjustable Rollformer→Straightening→Hydraulic Universal Punching & Cutting→Run Out Table | |||||

| Technical Parameters | |||||

| 1 | Suitable Material | Galvanized Steel Coil / Hot Rolled Steel / Cold Rolled Steel | |||

| 2 | Material Width | According to Profile Drawing | |||

| 3 | Material Thickness | 1.0-3.0mm | |||

| 4 | Roll forming speed | 10-15m/min (Exclude Punching & Cutting Time) | |||

| Equipment List | |||||

| 1 | Hydraulic Decoiler with Breaking device with coil car | 1 set | |||

| 2 | Entry Guide + Five(5)-Roll Leveler | 1 set | |||

| 3 | Hydraulic Pre-Punching Device | 1 set | |||

| 4 | Hydraulic Pre-Cutting Device | 1 set | |||

| 5 | Adjustable Roll Former (18 Roll Stations)with tooling | 1 set | |||

| 6 | Strengthening Device | 1 set | |||

| 7 | Run out table | 1 set | |||

| 8 | Siemens Or MitsubishiPLC and Touchable Screen for data processing and setting | 1 set | |||

Reliance CZ Purlin Roll Forming Machines

- C Purlin

- ZPurlin

- U Purlin or U Steel Profile

- Sigma Purlin Or Σ-purlin

- Eave Purlin

- Top Hat Purlins Or Omega Profile

- Angle Steel L Shape

C Purlin

C Purlins are accurately roll-formed by the CZ purlin roll forming machine. This kind of steel purlin is like the squared-off letter C. Cee Purlins are secondary steel framing members in prefabricated buildings for the roofs and walls. The raw material is mild steel, hot-rolled steel, cold-rolled steel, galvanized steel, etc. Standard C channel purlin is from 100mmto 300mm depth, and thickness ranges from 1mm to 3mm. The heavy-duty specification is from 100mmto 400mm depth, and thickness ranges from 2mm to 4mm.

Z Purlin

Z Purlins are accurately roll-formed by the CZ purlin roll forming machine. This kind of steel purlin is like the letter Z shape. Zee Purlins are horizontal beams that create the roof and wall joists of a steel building system. The Standard Zed purlins are from 100mm to 300mm depth, and thickness range from 1mm to 3mm. The heavy-duty Z purlin is from 100 mmto 400 mm depth, and thickness ranges from 2mm to 4mm. There are two kinds of Z section purlin with equal flanges or unequal flanges.

U Purlin or U Steel Profile

U purlins are fast produced by the CUZ purlin roll forming machine. This steel purlin is like the letter U shape. U purlins are longitudinal horizontal cold-formed members used as structural framing members to support the walls and roofs. The Standard U purlins are from 100mm to 300mm depth and thickness range from 1mm to 3mm. The heavy-duty Z purlin is from 100 mmto 400 mm depth, and thickness ranges from 2mm to 4mm.

Sigma Purlin Or Σ Purlin

Sigma purlin or Σ-purlin are roll-formed by the CZM purlin roll forming machine. Σ-purlins serve as framing members for industrial or commercial roofing and cladding support systems for steel structural buildings. The standard sigma purlins are from 140mm to 300mm depth and thickness range from 1mm to 3mm. The heavy-duty Σ-purlins is from 200 mmto 400 mm depth, and thickness ranges from 2mm to 4mm.

Eave Purlin

Eave purlins or eave strut are roll-formed by the CZ purlin roll forming machine. Eave struts are secondary steel framing members in the shape of a “C” with more than 90 degrees. You can use it at the eave of a steel structure building that supports roof and wall. The standard eave purlins are from 100mm to 300mm depth and thickness range from 1mm to 3mm.

Top Hat Purlins Or Omega Profile

Top hat purlin or omega profile are roll-formed by hat purlin roll forming machine. Top hat purlin is similar cross-section to a man’s top hat. Omega profiles are light gauge steel framing members used for roof and wall support in the steel framing system.

Angle Steel L Shape

Angle steel L shape is manufactured by angle steel roll forming machine using hot rolled steel. Angle steels are secondary steel framing members used to fasten panels to at the low end of walls and the upper end of rake walls. The material thickness range can be 1mm to 3mm or 2mm to 5mm.