Complete Door Frame And Door Panel Manufacturing Solution

- The raw material is galvanized steel, aluminum, stainless steel, etc.

- Thickness ranges from 0.8 to 2.0mm.

- Material yield strength 235Mpa.

- Integrateleveling, inline punching, notching, roll forming, flying cutting.

- Turnkey solutions are available for the various design of door frame and door panel roll forming machine.

Reliance Door Frame Roll Forming Machine Assure Your Hollow Metal Door Frame Quality Perfect

Custom Your Door Frame Roll Forming Machines

The steel door frame features high strength and long durability. Therefore It’s used in drywall and masonry metal door frames instead of traditional wooden frames. Reliance developed various steel door frame roll forming machines for different door frame designs. It’s also called door frame machine, door frame making machine, door frame rolling machine, steel door frame roll forming machine, door frame forming machine, etc.

What kinds of raw material of steel door frame roll forming machine can proceed?

Reliance door frame machine can proceed galvanized steel, stainless steel, aluminum alloy, etc. The most used thickness range is 0.8 to 1.2mm. The machine is also customized according to the customer’s requirement up to 2.5mm.

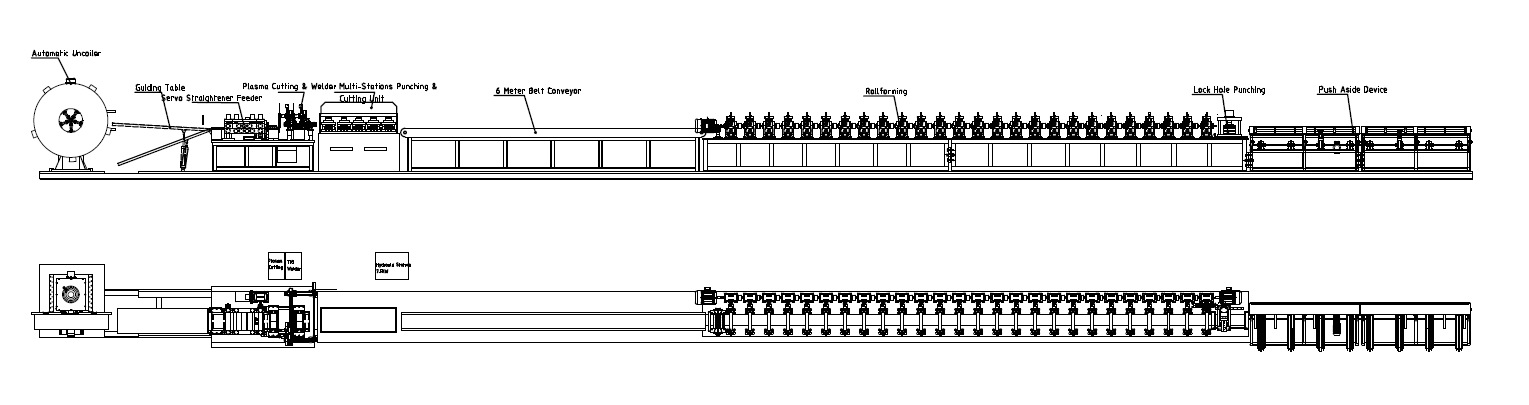

Workflow of steel door frame roll forming machine.

The classic workflow is as follows:

- Stop punching & stop cutting, which is running at a slow speed and cost-effective solution.

Uncoiler-> Non-power Leveling-> Hydraulic pre-punching -> Roll forming machine -> Hydraulic post cutting ( stop stationary type )

- Continuous punching & flying shear, which is at higher speed and high volume.

Uncoiler-> Powered Leveling-> Inline Hydraulic pre-punching -> Roll forming machine -> Hydraulic post cutting ( flying shear type )

Reliance Door Frame Roll Forming Machines Use the Famous Brand For Critical Parts

Storage & Logistics

The hollow metal door frame can use aluminum alloy as raw material. The aluminum door frame roll forming machine is a good solution with high productivity and high automation.

The hollow metal door frame can use stainless steel as raw material. The stainless steel door frame roll forming machine is an integrated solution with uncoiling, leveling, punching, notching, roll forming and cutting, etc.

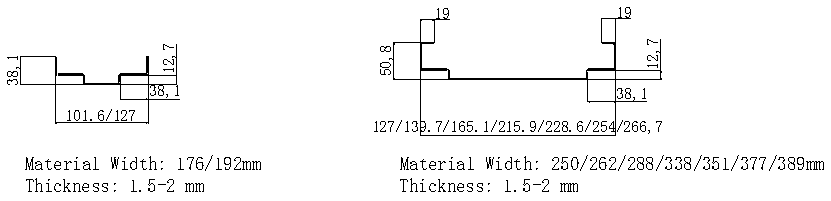

The single rabbet door frame is one type of common use door frame in the market. Reliance has the technology to make multi-width door frames in one machine.

The double rebated door frame is a popular hollow metal door frame in the market. Reliance has the technology to achieve to automatic width adjustable door frame roll forming machine.

The door panel is made by side-by-side door panel roll forming machine with two sets of rollers. It can be single sheet feeding production or continuous production.

According to the market need, the door frame width is always changed. Through reliance door, frame-making machine can make different width door frames in one machine.

Why Reliance Door Frame Roll Forming Machine

Flexible Hole patterns are customized according to your drawings. In the metal door frame, there are lock holes, hinge holes, screw holes, and notch in two ends. It will require high tolerance of hole locations for installation.

- Reliance door frame machine is running with a high tolerance of hole location and length. Through the servo feeder to control the feeding step, the punching system can achieve high tolerance results. The hole location tolerance can be controlled at ±0.5mm. Especially the head and tab of the door frame, it will impact the installation of the left, right, and top frame.

- Flexible roll forming section can produce an adjustable width door frame. In the market, there are requirements for the different width door frames. Therefore, the Reliance door frame machine can make more specifications in one machine and help you to provide more possibilities for market needs.

- Different cutoff modes are available for your business. There are several end types of door frames. The most common is the straight end of the head and tab of the door frame. It will require manual weld together. The 2nd type is with holes and tabs in the ends, and the tabs can be inserted into the holes and lock together. The 3rd type is with the unique hole design between the left, right, and top door frame. It will make the left, right, and top door frame in one piece. We can provide these three options for your door frame applications.

- Different door frame cross-sections are available for customized design. The most common door frame is a single rebate& double rebate door frame. Our engineer team also can design and make the door frame roll forming machine according to your need.

Please don’t hesitate to contact our expert for more information.

- Parameters

- Equipment list

- Layout Drawing

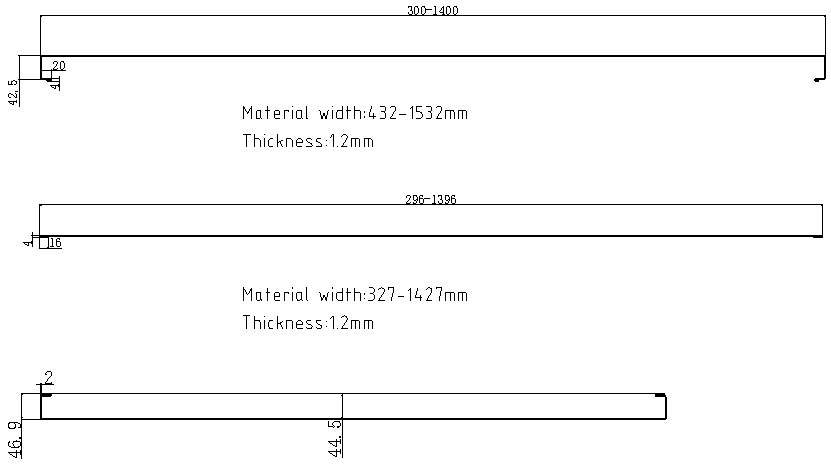

- Profile Drawing

| Technical Parameters | ||||

| 1 | Suitable Material | Galvanized Steel Coil | ||

| 2 | Material Width | According to Profile Drawing | ||

| 3 | Material Thickness | 0.8-1.2 mm | ||

| 4 | Roll forming speed | 10-15 m/min (Exclude Punching & Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic Decoiler | 1 set | ||

| 2 | Loading Coil Car (Option) | 1 set | ||

| 3 | Leveler | 1 set | ||

| 4 | Servo Roll Feeder | 1 set | ||

| 5 | Online Hydraulic Punching Equipment | 1 set | ||

| 6 | Rollformer with tooling | 1 set | ||

| 7 | Straightening Device | 1 set | ||

| 8 | Flying cutoff machine | 1 set | ||

| 9 | Run Out Table or automatic stacking device | 1 set | ||

| 10 | Siemens Or Mitsubishi PLC and Touchable Screen are used for data processing and setting. | 1 set | ||

Reliance Door Frame Roll Forming Machines

- Aluminum Door Frame

- Stainless Steel Door Frame

- Single Rabbet Door Frame

- Double Rebated Door Frame

- Door Panel

Aluminum Door Frame

The aluminum door frame is precisely roll-formed by door frame roll forming machine. Aluminum door frames are lighter and faster to install compared to a steel door frame. The regular thickness range is 0.8 to 1.2mm.

Stainless Steel Door Frame

The stainless steel door frame is precise roll-formed by the door frame roll forming machine. Stainless steel door frames are corrosion resistant, fire-resistant, and offer unsurpassed durability. The typical material is 201, 304, at 0.8 to 1.2mm thickness range.

Single Rabbet Door Frame

The single rabbet door frame is precise roll-formed by the door frame roll forming machine. The single rabbet door frame has one single rabbet and usually required on openings where the wall thickness.

Double Rebated Door Frame

The double rebated door frame is continuous roll-formed from steel coil by door frame roll forming machine. The double rabbet door frame gets its name from the fact that the door frame has two rabbets. These rabbets can be specified as equal or unequal in dimension.

Door Panel

The steel door panel is roll-formed from steel coil by adjustable door panel roll forming machine. The door panel consists of an internal panel and an exterior panel. The material thickness range is 0.8-1.2mm.