Custom Your Standing Seam Roofing Solutions

- The raw material is prepainted steel, aluminum, galvanized steel, galvalume, galvalume, etc.

- Yield strength is capable of full hard G550 raw material.

- The thickness range is between 0.3to 1.2mm.

- Variety standing seam metal roofing design.

- Line speed up to 30m/min.

- Integrate standing seam metal roof manufacturing solutions

Reliance Standing Seam Roof Machine Assure Your Standing Seam Metal Roof Quality Perfect

Custom Your Own Standing Seam Roof Machine

Standing seam roofing is a fully interlocking roof panel system with many advantages. There are mechanical seam, snap-lock seam, single lock, etc. It looks better, lasts longer, and provides superior waterproofing than ordinary metal roofing. If you are a seam metal roofing contractor, your business depends on a high-quality standing seam machine. It will offer decent quality standing seam metal roofs for your clients.

It’s also named standing seam roll forming machine, standing seam roll forming machines for sale, standing seam roll former, standing seam roll former for sale, standing seam roof panel machine, standing seam forming machine, etc. Standing seam metal roof machine price depends on the profile drawing and exactly technical requirements. Please don’t hesitate to contact us.

Reliance Standing Seam Roof Machine Use the Famous Brand For Critical Parts

Storage & Logistics

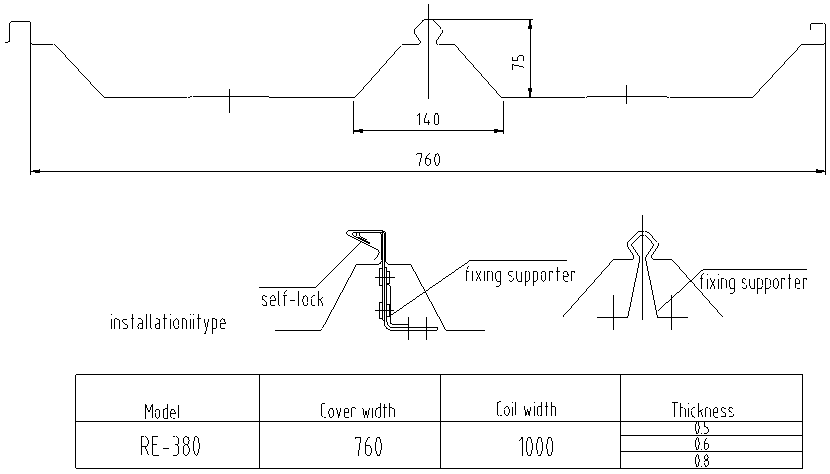

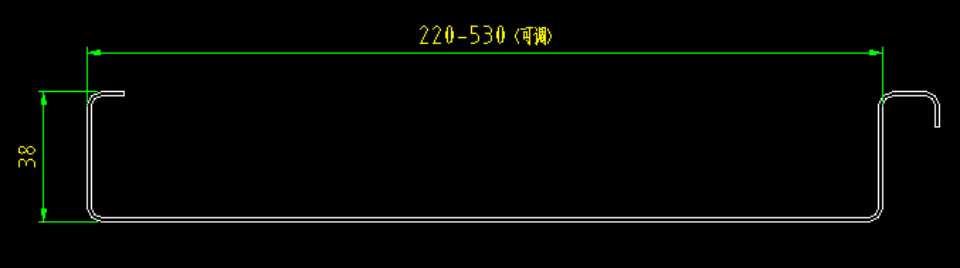

The low slope standing seam roof is mechanically-locked type metal roof systems. There are two kinds of mechanical seams: Single-lock (one fold, 90-degree seam), Double-lock (two folds, 180-degree seam). Reliance low slope standing seam roof machine for sale mostly produces 1″& 1.5″ seam height and panel width up to 18″ or more. It can produce thickness up to 1.2mm and different raw materials and adjustable width.

Reliance low slope standing seam roof machine mostly produces 25 & 38 height and 500mm width in max. 1.2mm thickness material.

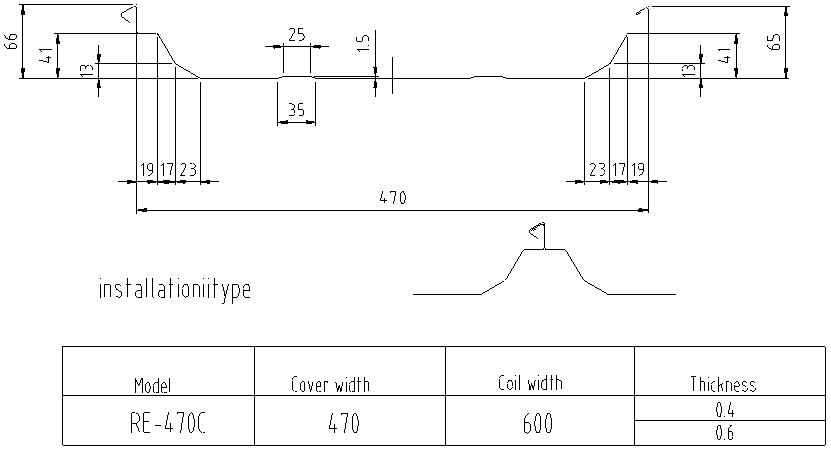

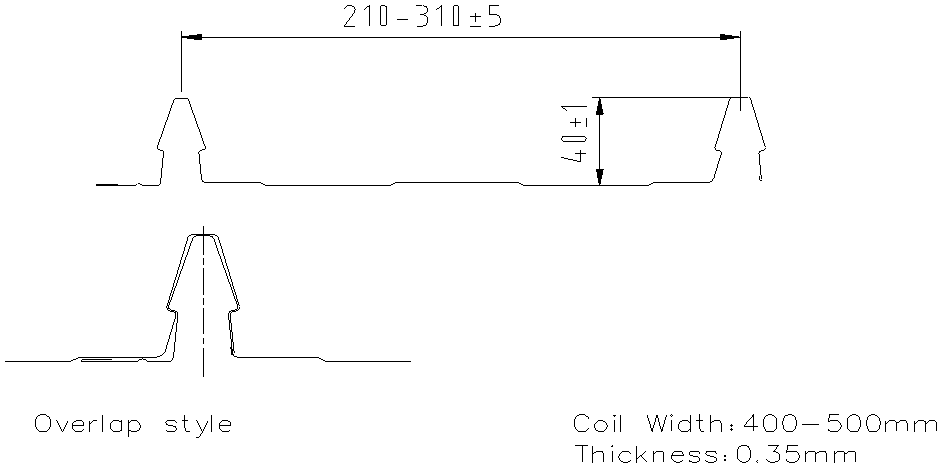

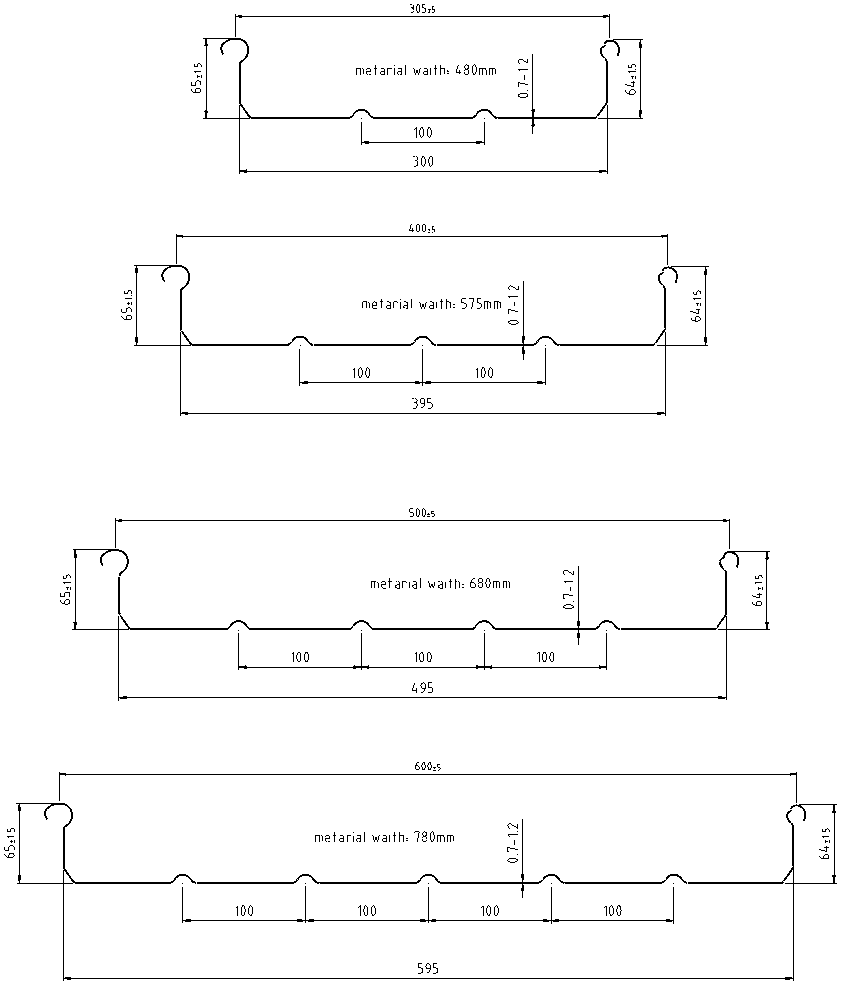

Snap lock standing seam roof features a fastening side ridge that is hidden by the ridge of the next panel. The snap-lock standing seam roof system is secured to the roofing deck by concealed clips or fasteners. Reliance snap lock standing seam roof machine for sale can achieve flat panel width adjustable. The precise roll forming process will assure the final standing seam roof overlap tightness.

Reliance snap lock standing seam roof machine can produce snap lock standing seam roof in various designs.

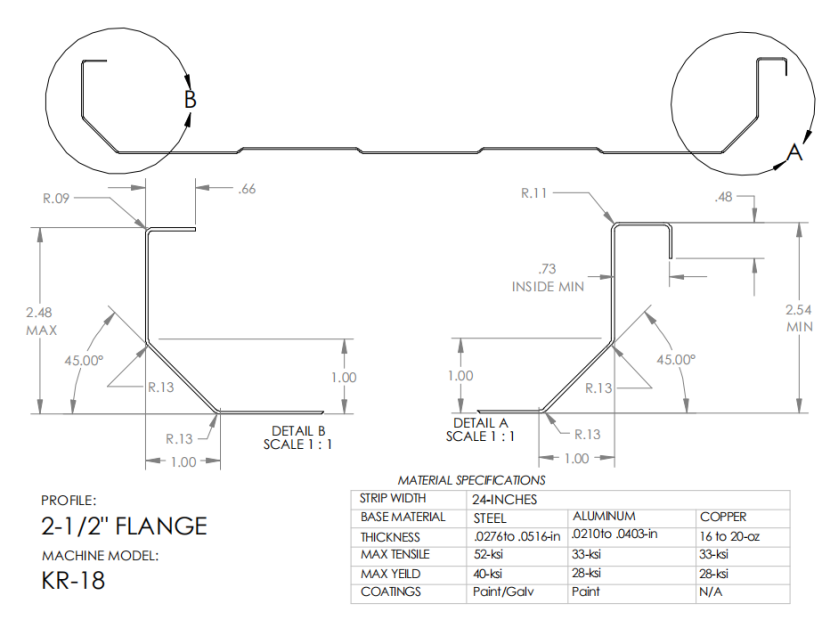

KR18 & KR24 are snap together trapezoidal double lock standing seam roof. It’s mostly used in Mexico and South American countries. Reliance KR18 & KR24 standing seam metal roof machine for sale can produce these two models standing seam roofs.

Reliance KR18 & KR24 standing seam roof machine can produce both KR18 & KR24 standing seam roof up to max. 1.2mm thickness.

Klip-Lok 406 and Klip-Lok 700 standing seam roof were developed by LYSAGHT. Clip-Lock standing seam roof is designed by TAYLOR METAL. It’s mostly used in South Africa and African counties. Reliance develops a standing seam metal roof machine for sale to produce a similar standing seam roof system.

Reliance Klip-Lok & Clip-Lock standing seam roof machine can produce klip-lok 700 in max. 0.8mm thickness.

Aluminum standing seam roof is more corrosion-resistant, softer, and less of load. It’s suitable for a large span and arch panel.

Reliance aluminum standing seam roof machine can produce various designs of standing seam roof by aluminum alloy.

The portable standing seam roof machine is developed to meet the production on site. The machine is very light and easy to move.

Reliance standing seam roof machine can be lightweight and portable design for on-site production.

Why Reliance Standing Seam Roof Machine

- An adjustable standing seam machine can make different pan width seam roofing panels in one machine. Through positioning motors, linear guider, and ball screws, the operator can set the size in the touch screen, and the machine will automatically change the size.

- If you have some large span projects, it’s a problem for transport long seam roofing sheets. Our portable standing seam roll forming machine for sale can move to the site and produce long roofing sheets.

- If need higher capacity, Reliance can provide max. 50m/min standing seam roll former solutions to support it.

- If you need a convex and concave curved standing seam roof, our curving machine can achieve convex, concave, and S shape curving. If Aluminium sheet 0.7-1.2mm thickness, can convex curving min.radius 3 meters, and concave curving min.radius 6 meters.

- To help customers startup their own business, we can provide the installation, training service, and guide customers in the projects.

- Parameters

- Equipment list

- Layout Drawing

- Profile drawing

| Technical Parameters | ||||

| 1 | Suitable Material | PPGI Steel Coil /Galvalume Steel Coil / Aluminium Coil / Galvanized Steel Coil | ||

| 2 | Material Width | According to Profile Drawing | ||

| 3 | Material Thickness | 0.4-0.8 mmPPGI Steel Coil / 0.7-1.2 mm Aluminium Coil | ||

| 4 | Roll forming speed | 10-20 m/min (Exclude Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic Decoiler with coil car | 1 set | ||

| 2 | Rollformerwith tooling | 1 set | ||

| 3 | Hydraulic cut-off machine | 1 set | ||

| 4 | Run out table | 1 set | ||

| 5 | Siemens Or MitsubishiPLC and Touchable Screen are used for data processing and setting | 1 set | ||

| 6 | Curving machine, Convex, Concave or “S” curving | 1 set | ||

| 7 | Automatic Seamer ( For some standing seam roof ) | 1 set | ||