Your Reliance Cable Tray Manufacturing Solutions

- The raw material is mild steel, galvanized steel, stainless steel, aluminum alloy, etc.

- Thickness ranges between 0.8 to 3.0mm.

- The standard machine is width range 50mm to 600mm, height range 25mm to 200mm.

- PLUS machine is width range 100mm to 900mm, height range 25mm to 200mm.

- Hole patterns are according to your design.

- Integrate continuous punching, roll forming, and cutting solutions.

Reliance Cable Tray Roll Forming Machine Assure Your Cable Tray Quality Perfect

Custom Your Own Cable Tray Roll Forming Machines

In the electrical wiring of buildings, the cable tray system is used to support insulated electrical cables, power distribution, control, and communication. Cable trays are a necessary part of industrial and commercial builds by providing quick, economical, and flexible solutions.

If you are a cable tray contractor, a cable tray roll forming machine is a mass production solution of all different width and height cable trays. Compare to made by press brake, the roll forming process is flexible sizes and high output up to 10m/min.

Reliance Cable Tray Roll Forming Machine Use the Famous Brand For Critical Parts

Storage & Logistics

Perforated cable tray is cold-formed by cable tray roll forming machine. Perforated cable tray is with uniform holes in the base and side. It’s helpful for cables protection and ventilation. The standard perforated cable tray is thickness range 0.8 to 2.5mm, depth 25 to 100mm and width 50 to 600mm. The raw material is mild steel, galvanized steel, powder-coated steel, stainless steel 304 and 316, aluminum alloy, etc.

Reliance perforated cable tray roll forming machine can proceed material up to 3.0mm thickness, 200mm depth to 900mm width.

Ladder cable tray is cold-formed by cable tray roll forming machine. Ladder cable tray consists of two parallel side rails connected by individual transverse rungs. Ladder cable trays are usually made of stainless steel, aluminum, hot-dipped galvanized steel, pre-galvanized steel, stainless steel. This design is lightweight and maximum ventilation for power cable or control cable support system.

Reliance ladder cable tray roll forming machine can produce both side rails and rungs according to your drawings.

Trunking cable tray is cold-formed by cable tray roll forming machine. Trunking cable tray is a durable rectangular enclosure in which wires and cables are placed inside. It’s typically used in the indoor inside panels to distribute power insulated cable lines. You can use high strength aluminum alloy, or hot-dip galvanized steel. Due to the high load capacity and robust design, It requires fewer fastening places so that it can save working time and materials.

Reliance trunking cable tray roll forming machine can produce trunking cable tray in different materials.

Channel cable tray is cold-formed by cable tray roll forming machine. Channel cable tray is an enclosed section which is a ventilated or solid bottom section. It’s used to protect single power cable, multiple control, or single circuit cables. The materials are available with stainless steel, carbon steel, aluminum alloy, etc.

Reliance channel cable tray roll forming machine can produce different channel width and height according to requirements.

Aluminum cable tray is cold-formed by cable tray roll forming machine. Aluminum cable tray is with much lighter, anti-corrosion, and high strength features. It’s much lighter weight so that aluminum cable tray is easier to install than steel cable tray. The most used several patterns are channel design, perforated design, and ladder design, etc.

Reliance aluminum cable tray roll forming machine can produce different types of cable tray by aluminum alloy.

Stainless steel cable tray is cold-formed by cable tray roll forming machine. Stainless steel cable tray is made of stainless steel 304, 316. The most used designs are channel cable tray, ladder cable tray, perforated cable tray, etc. The main advantage is anti-corrosion for the working environment.

Reliance stainless steel cable tray roll forming machine can produce different designs cable tray by stainless steel.

Galvanized cable tray is cold-formed by cable tray roll forming machine. Galvanized cable tray is made of galvanized steel. It’s mostly used in low voltage, telecommunication, and fiber optic cables. The most used designs are channel cable tray, ladder cable tray, perforated cable tray, etc.

Reliance galvanized cable tray roll forming machine can produce different kinds of cable tray by galvanized steel.

Trapezoidal roof is with ribbed trapezoidal shapes across the metal roof

Why Reliance Cable Tray Roll Forming Machine

- The cable tray projects always require multi sizes and hole patterns for different buildings. Therefore, cable tray roll forming machine is designed for multi-sizes and high capacity production.

- Reliance focus on improving the capacity and cost-effective solutions for cable tray productions. Our cable tray roll forming machine has the following advantages

- Automatic width change and height change, the operator only set cable tray sizes in the touch screen, the roll former will automatically change the size Width 50 to 600mm, height 25 to 200mm. In some cases, width 100 to 900mm / 1000mm, height 25 to 200mm

- Customized punching design according to your drawing. Through the innovation of punch mold, the core-pulling punch mould can save much cost for investing mold and save time to change the mould.

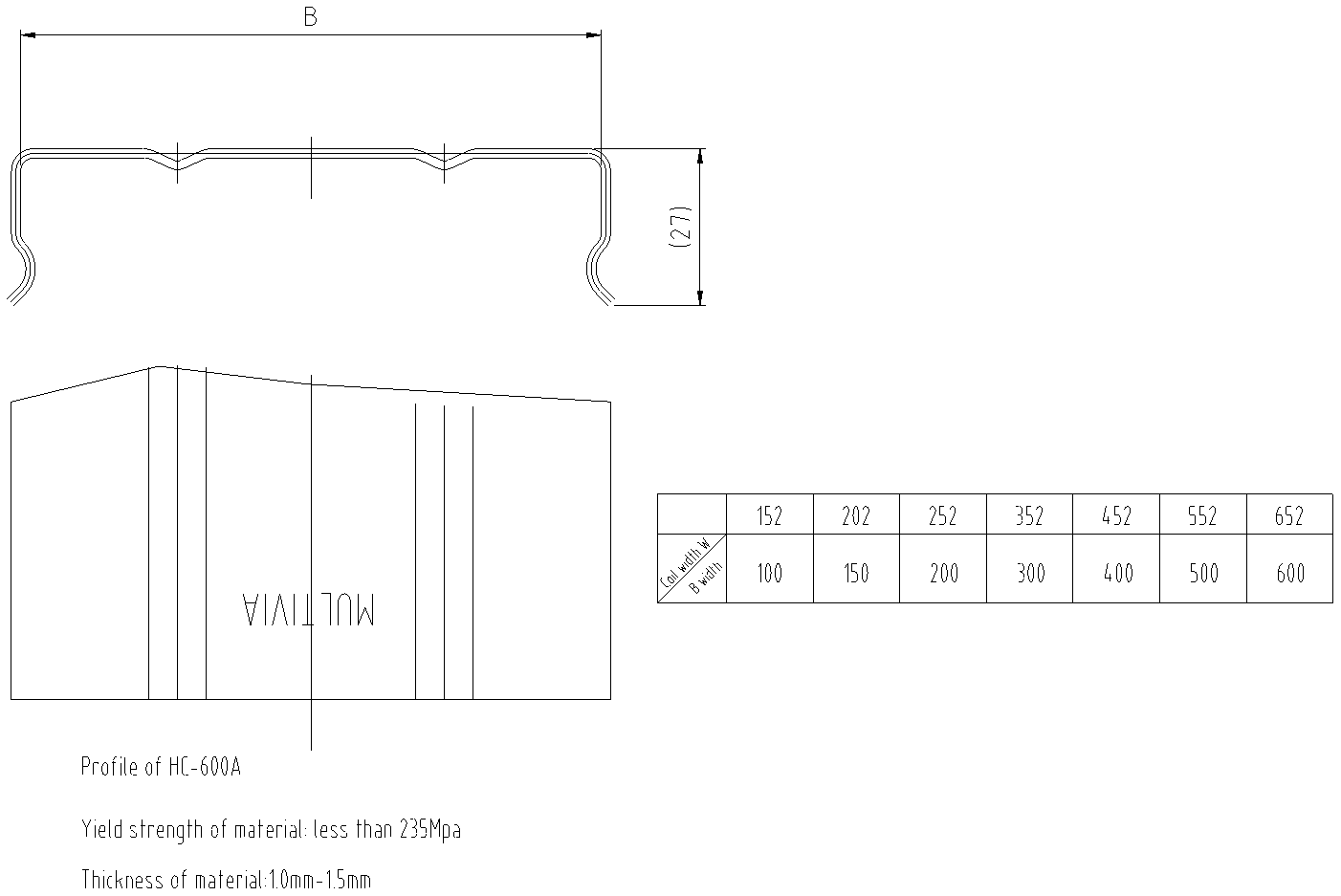

- Reliance cable tray roll forming machine combines decoiling, punching, roll forming, and cutting in one machine.

- Turnkey solutions. Reliance team will guide you to build the cable tray factory from start. The technician is available to install and train in your factory.

- Parameters

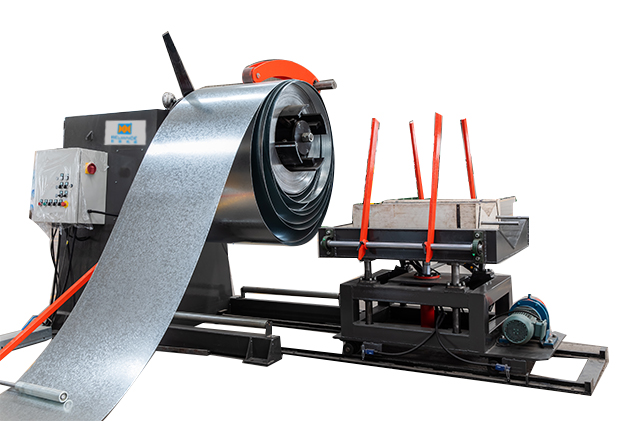

- Equipment list

- Layout Drawing

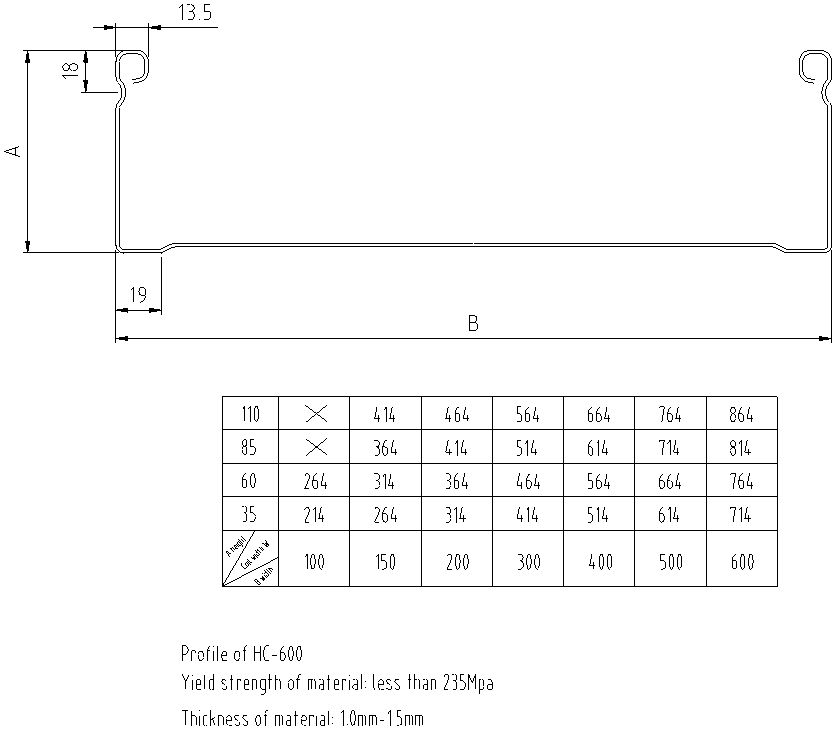

- Profile drawing

| Technical Parameters | ||||

| 1 | Suitable Material | Galvanized Steel Coil, stainless steel, aluminum alloy, etc. | ||

| 2 | Material Width | According to Profile Drawing | ||

| 3 | Material Thickness | 0.8-3.0 mm | ||

| 4 | Roll forming speed | 10-15m/min (Exclude Punching & Cutting Time) | ||

| Equipment List | ||||

| 1 | Hydraulic Decoiler with coil car | 1 set | ||

| 2 | Leveler | 1 set | ||

| 3 | Servo Roll Feeder | 1 set | ||

| 4 | Hydraulic Pre-Punching Or Mechanical Punching Press | 1 set | ||

| 5 | Hydraulic Pre-Cutting Or Mechanical Shearing Machine | 1 set | ||

| 6 | Powered RollerConveyor | 1 set | ||

| 7 | Cantilevered Type Rollformerwith tooling | 1 set | ||

| 8 | Run out table | 1 set | ||

| 9 | Siemens Or MitsubishiPLC and Touchable Screen are used for data processing and setting | 1 set | ||