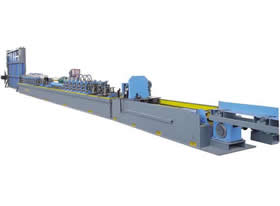

High Frequency Steel Tube Mill

- Model : 140mm×4.5mm-RE140

- Categories : Tube Mill

- Payment Terms : L/C,T/T

- Brand Name : Reliance

- Place of Origin : China

- Application

- Technical Parameter

- Equipment List

- Components

- FAQs

- Catalog

High frequency steel tube mill is designed to produce round tube diameter of 60–140mm, and wall thickness of 1.5-4.0mm.

The High frequency steel tube mill is designed for forming pipes and tubes on one continuous line with steel strip, which was slit by slitting line to fit pipe or tube diameter. Using high frequency induction heating, this line is capable of producing section material of various diameters and sizes by squeezing weld seam together into closed shape.

The application of advanced aperture technology, PLC automatic control system and

Digital speed regulating unit ensure that the production line works reliably and operates and maintains easily.

Application

Furniture/ornamental for high quality tube with aesthetic surface

Automotive to comply with the high demand standard of automotive industry

Mechanical tube for precision tube as well as for high-resistant material

Structural high productivity and good mechanical properties

Conduit electric cables conduits

Water/gas to comply with the norms for

Heat exchanger for pressure, boiler and heat exchanger tubing

API for oil and natural gas

Steel profiles

Work Flow:

Coil loading—Uncoiling—Pinching & Leveling—End Shearing–‐Strip joining—Horizontal Spiral Accumulator—Forming,–‐HF Welding–Outside burr removal–Water Cooling–‐Sizing & straightening–‐Measuring roll—Flying saw cutting—Run out conveyor

| Raw material | Hot rolled steel, cold rolled steel, galvanized steel |

| Round tube outer diameter | 60-140mm |

| Wall thickness Round tube | 1.5-4.0mm |

| Square tube | 50×50- 110×110 |

| Rectangular tube | 60×40-150×70 |

| Wall thickness Square & Rectangular tube | 3.5mm |

| Tube welding speed | 20-60m/min |

| Main DC Drive | 132kW×2 |

| High frequency welder | 400kW |

| Entry section | ||||

| Uncoiler | Single Mandrel Hydraulic Uncoiler | |||

| Shear & End Welder | Semi-Automatic | |||

| Hydraulic shear | ||||

| Accumulator | Horizontal Spiral Accumulator | |||

| Forming section | ||||

| Side guide & Flatten | Seven flattening roll | |||

| Round shape Forming | Conventional mill | Cassette-Bed Quick change | ||

| Welding section | ||||

| Seam guide roll stand | ||||

| Squeeze roll stand | ||||

| Outer weld bead removal | ||||

| H.F.Welder | Solid State | Vacuum Tube | ||

| Cooling unit | ||||

| Sizing & strengthening section | ||||

| Sizing | Conventional mill | Cassette-Bed Quick change | ||

| Turk Head | Single Station | |||

| Measuring roll stand | Speed & length measuring | |||

| Cutting & discharging | ||||

| Flying Saw | Pneumatic Friction Saw | |||

| Run out conveyor | One side | Double side | ||

1.Uncoiler

2.Welding table and shear

3. Spiral Horizontal Accumulator

4.Forming & Sizing Unit

5.Cutting Saw

6.Solid State H.F. Welder

7.Mould and spare parts