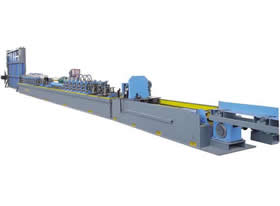

High Frequency Carbon Steel Tube Mill Line

- Model : 219mm×8.0mm-RE219

- Categories : Tube Mill

- Payment Terms : L/C,T/T

- Brand Name : Reliance

- Place of Origin : China

- Application

- Technical Parameters

- Equipment List

- Components

- FAQs

- Catalog

Furniture/ornamental for high quality tube with aesthetic surface

Automotive to comply with the high demand standard of automotive industry

Mechanical tube for precision tube as well as for high-resistant material

Structural high productivity and good mechanical properties

Conduit electric cables conduits

Water/gas to comply with the norms for

Heat exchanger for pressure, boiler and heat exchanger tubing

API for oil and natural gas

Steel profiles

Work Flow:

Coil loading—Uncoiling—Pinching & Leveling—End Shearing–‐welding—Horizontal Spiral Accumulator—Flattening—Forming,–‐HF Welding–Outside burr removal–Water Cooling–‐Sizing & straightening–‐Measuring roll—Flying saw cutting—Run out conveyor

| Raw material | Hot rolled steel, cold rolled steel, galvanized steel |

| Round tube outer diameter | 114-219mm |

| Wall thickness Round tube | 3.0-8.0mm |

| Square tube | 90×90-100×100, 125×125, 150×150,170×170, etc |

| Rectangular tube | 60×125, 80×150,125×170,150×200, etc |

| Wall thickness Square & Rectangular tube | 6.0mm |

| Tube welding speed | 15-40m/min |

| Main DC Drive | 200kW×3 |

| High frequency welder | 800kW |

| Entry section | |||

| Uncoiler | Hydraulic Uncoiler with loading coil car | ||

| Coil opener | Pressure pad + Peeler table | ||

| Leveling machine | Pitch roll + 5-Levelling roll | ||

| Shear & End Welder | Semi-automatic CO2 air-protection welding | ||

| Hydraulic shear | |||

| Accumulator | Horizontal Spiral Accumulator | ||

| Forming section | |||

| Side guide & Flatten | Seven flattening roll | ||

| Round shape Forming | Conventional mill | ||

| Welding section | |||

| Seam guide roll stand | |||

| Squeeze roll stand | 5-Roll type | ||

| Outer weld bead removal | |||

| H.F.Welder | Solid State | Vacuum Tube | |

| Air cooling + water Cooling unit | |||

| Sizing & strengthening section | |||

| Sizing | Conventional mill | ||

| Turk Head | Single Station | ||

| Measuring roll stand | Speed & length measuring | ||

| Cutting & discharging | |||

| Flying Saw | Pneumatic Friction Saw | ||

| Run out conveyor | One side | ||

1.Uncoiler

2.Welding table and shear

3. Spiral Horizontal Accumulator

4.Forming & Sizing Unit

5.Cutting Saw

6.Solid State H.F. Welder

7.Mould and spare parts